Six things I learned on a works outing to Hitachi’s Train Building Factory in County Durham

1.We live in a world of mysterious blank big sheds inside which much of the economy happens.

So good on Hitachi on being so open to visitors in letting people like us have a look at what goes on in their factory and to see some new trains being born. People love to see what goes behind the scenes and there is lots of scope for more of the transport industry to do more of it - Hitachi certainty do as another group was ready to do a tour as we left. And very high tech the trains are too (currently the factory is churning out the new IEP high speed trains for the East Coast Main Line and electric trains for the Scottish central belt) loaded with sensors and threaded through with kilometres of cabling.

2. I like a new train, I like it if it gets me there a bit quicker.

It's nice if it has a racy nose cone. But really what I'm interested in (and would swap a longer journey time for) is are the seats going to be comfortable and will I be able to move my elbows sufficiently to do a bit of work on it. Frustrating therefore how boring, uncomfortable and cramped most interiors for modern trains are - especially when gazillions are spent on their engineering aspects. Symptom of a railway run by engineers and financial engineers - and overseen by an absentee landlord at DfT. None of which is Hitachi's doing as seat spec is down to the DfT and the franchisee. Word is IEP East Coast trains are going to have more comfortable seating given recent backlashes against ironing-board seats elsewhere. We shall see.

3. The factory employs a lot of people to put parts together and assemble and test the trains.

They are also seeking to involve the local supply chain in supplying more of those parts (70% of parts in the IEP come from the UK they say). All good but the question remains how much of the clever parts of new trains could be procured from the UK in new UK trains (for now the body shells, with a fair amount of kit already built in, comes from Japan) and the traction packages, air conditioning, diesel power packs and universal access toilets are all imported. I'm in no way singling out Hitachi on this issue as it's a Government specification issue. Roger Ford, in his informed sources, column has argued that there should be a minimum spec for high value components from the UK for the UK. The focus we currently have on train and bus building plants (and the outcry if they come under threat) needs to be balanced with attention to how they relate to the supply chain (particularly the advanced manufacturing end of the supply chain).

4. Hitachi are doing some close working with a nearby college to attract young people into the industry (though young peoples' primary engineering aspirations are aerospace or Formula One not trains they say).

You can never start too early therefore and thus they are working with primary schools to give kids some fun in a location they are unlikely to forget soon and to sow some seeds as to what their future might hold before they start to copy the views of their peers as to what's for them and what is not.

5. How few people who build new public transport vehicles use public transport to get there. We got there on the Darlington to Bishop Auckland branch line (alighting at Heighington) with its less than high tech Pacer trains and hourly service. But at shift change at Hitachi there was a whirlwind of activity in the car park but none of the workforce joined us on the rather grim walk back to the station. There were a couple of bus stops on the road back as well (with shelters) but with no maps and no timetable information - the signage to the station was also poor. Efforts are being made to improve things (with a new earlier service to the station for the start of the early shift) however overall very reminiscent of the ignored and underwhelming public transport access to the Optare bus building factory east of Leeds - which everyone also drives to.

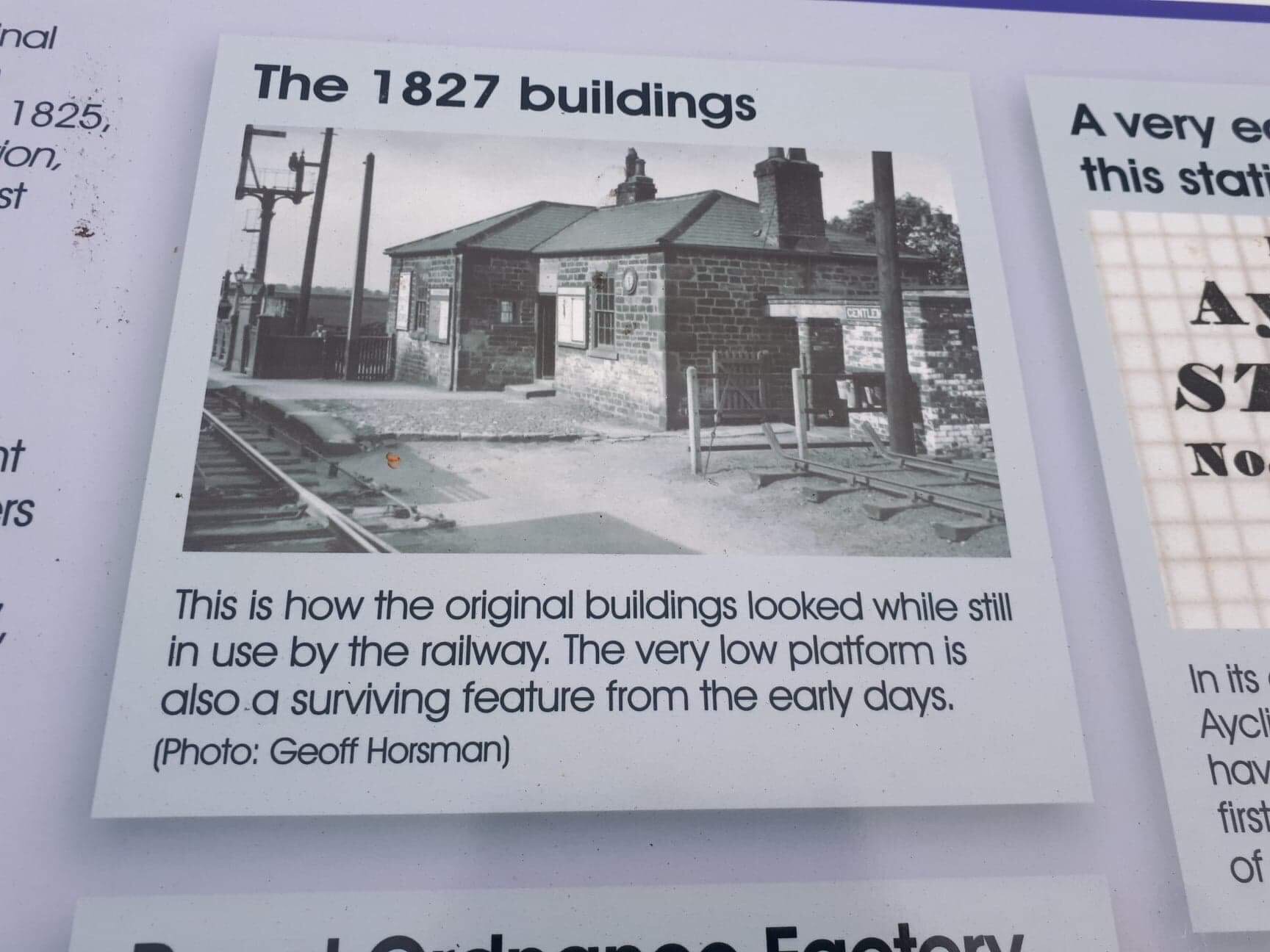

6. The Bishop Auckland branch line may feel like a backwater today but part of it is the route of the original Stockton and Darlington railway. You can define what was the first railway in a lot of ways. But this was the world's first public railway which used steam locomotives for freight alongside a horse drawn (at first) passenger service. A boarded up pub next to Heighington station can claim to be the oldest extant station building at a working railway station in the world. It's also where George Stephenson's Locomotion Number One took to the rails for the first time. And if that wasn't enough it's also home to one of the oldest working signal boxes in the country. With the railway museum at Darlington North Road and the NRM base at Shildon further down the line here's hoping even more can be made of this railway's historical interest and credentials in the run up to 2025 (the bicentennial of the opening of the Stockton and Darlington).